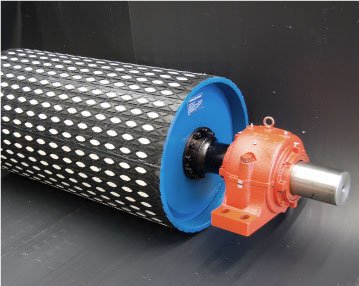

Custom-designed Conveyor Pulleys

Our conveyor pulleys are all designed to deliver top-quality service with optimal endurance.

We can custom design and fabricate any conveyor pulley to suit all functions for mining, manufacturing, quarries and even small-scale, lightweight industrial applications.

We offer a wide range of manufacturing options from mild steel and stainless steel, right through to composite materials.

Our custom engineered conveyor pulleys are designed and manufactured for every application. We also install bearings and pulley lagging should they be required. All of our conveyor pulley’s come with quality certification.

Conveyor Pulley Services

Similarly, Belle Banne Conveyors are committed to the specialised needs and circumstances of our clients. Our extensive range of services include solutions like:

In addition to these factory services, we offer on-site pulley services such as:

Conveyor Pulley Types and Components

To accommodate the wide range of industries we serve, Belle Banne Conveyors offers an extensive selection of conveyor pulley types and components to choose from. Our experts are armed with years of experience in the field of materials handling, and paired with our dynamic research and development department, they will provide the best possible solution for you. This includes:

Our conveyor pulley range includes a selection of locally-made and imported systems, backed by in-house design and engineering teams at Belle Banne Conveyors. We offer specialised pulleys like winger, chevron, and bulk pulleys to suit any job for any industry.

Conveyor Pulley Lagging Types

At Belle Banne Conveyors, we understand the necessity for peak performance. That’s why we ensure our pulley lagging components are all quality-tested to provide the best performance and service life. Our experts can help you pick out the most suitable lagging material for your application.

The conveyor pulley lagging types we offer in both hot and cold applications include:

The Belle Banne Conveyors Benchmark

We work our innovative designs to our customer’s specifications, ensuring they are customised and purpose built for each unique application and environment.

We focus on achieving the greatest return on investment for our client’s assets through solutions that guarantee the best operational outcomes with minimal downtime.